Sustainable Supply Chain

Supply Chain Sustainability Policy

With regard to supply chain management, Nuvoton Technology not only complies with basic industrial safety and environmental protection requirements, but also has formulated supplier sustainability management policies and incorporated ESG as part of the supplier evaluation and audit, in an attempt to exert its own influence. Together with its suppliers, Nuvoton values and promotes corporate sustainability so as to achieve the vision of sustainable supply chain development.

On the basis of the principle of international human rights protection, Nuvoton Technology attaches great importance to the issue of conflict metals and is committed to no use of illegally mined metals in violation of human rights in its products, raw materials, and production processes. Also, relevant suppliers are required to sign the "Declaration of Non-Use of Conflict Minerals."

Nuvoton Technology concerns itself with the labor rights in the supply chain, demanding suppliers to comply with the relevant laws and regulations in the countries they operate and the requirements of relevant international industry codes and standards, including the Responsible Business Alliance (RBA) Code of Conduct as well as any changes or amendments thereto. All the suppliers on the supply chain are required to sign the “Commitment to Comply with the Code of Conduct” and the “Confidentiality Agreement.”

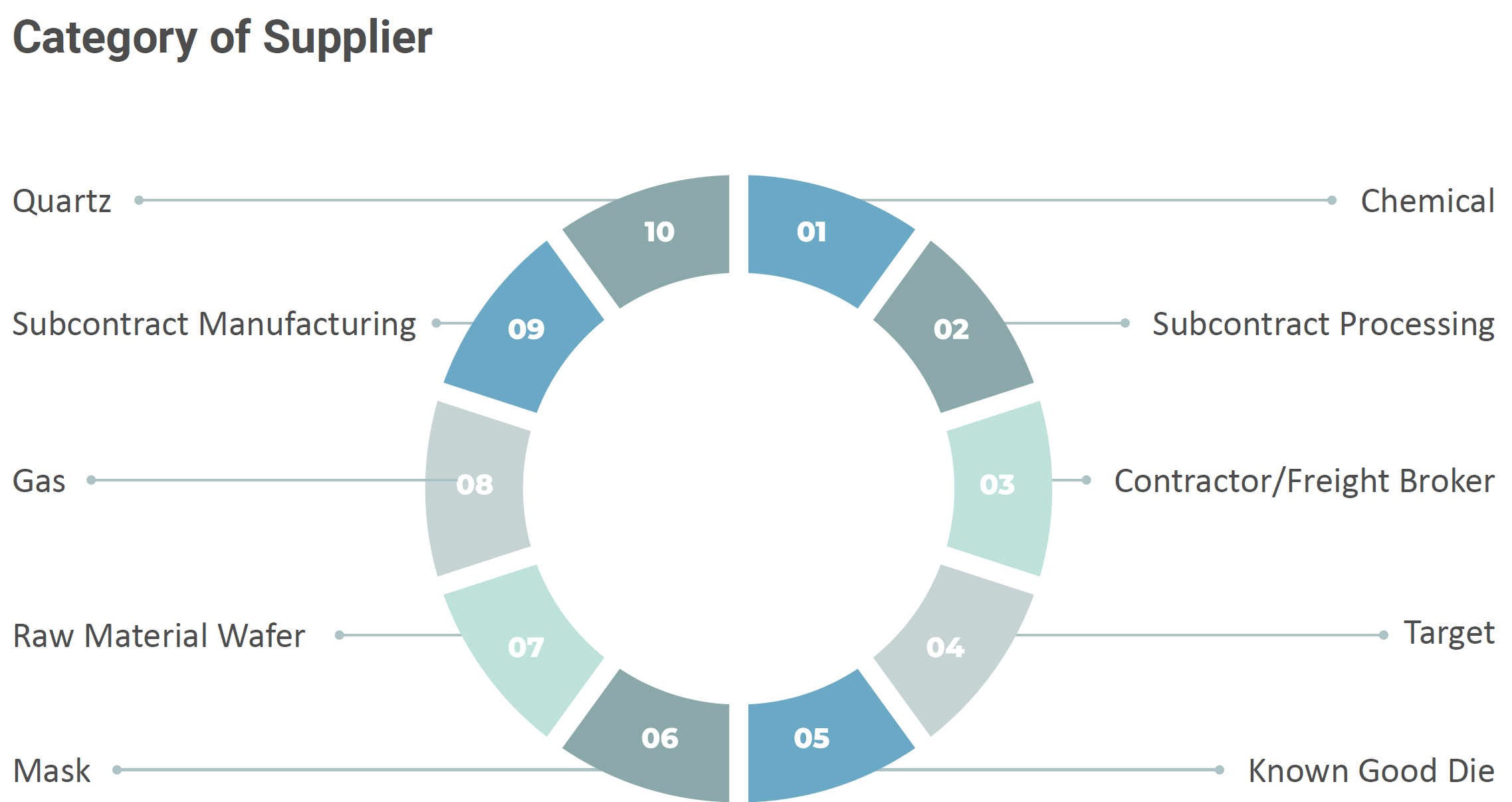

Nuvoton Technology operates in IC design in the upstream and wafer foundry services in the midstream of the semiconductor supply chain. Thus, it needs to work closely with suppliers in the industry chain to form a partnership of professional division of labor and mutual cooperation. As an iconic company in the global semiconductor industry, it collaborates with its suppliers to create a sustainable supply chain, which is one of the key indicators for the sustainable development management at Nuvoton.

Local Procurement

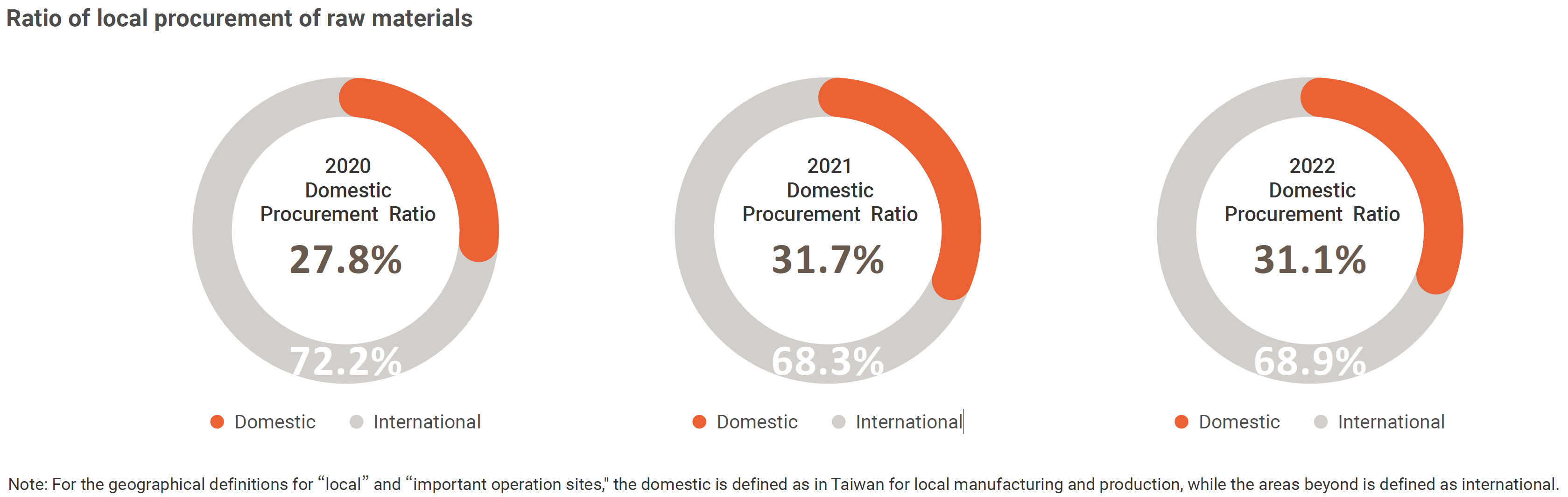

Since its establishment, Nuvoton Technology has been aiming to foster a long-term, stable supply chain for semiconductors business. In recent years, we have been committed to local manufacturing of raw materials with the goal of transportation cost reduction, risk diversification, and carbon emissions reduction. Furthermore, we seek to increase job opportunities by supporting local production. The ratio of local procurement of raw materials in 2022 was 31.1%, which is a slight decrease by 0.6% compared with that in 2021, due to the limitations of our industrial characteristics. We shall maintain a close relationship with local suppliers in the future. Upholding the prerequisite of a win-win scenario for all, we continue to work together to reduce costs and risks. Local procurement remains an important strategy at Nuvoton Technology in supplier selection.

Selection of New Suppliers

Evaluations are conducted regarding quality, price, eco-friendliness, etc. Any supplier that meets the requirements of Nuvoton Technology is to sign “Commitment to Comply with the Code of Conduct” and “Confidentiality Agreement” of the Company as well. Also, the supplier is required to faithfully execute all sales and transactions and shall not damage the interests and image of Nuvoton Technology. As such, it may become a qualified supplier.

Supply Chain Management Approach

Nuvoton Technology manages and mentor the qualified suppliers following the three aspects as follows. Meanwhile, suppliers are required to obtain third-party quality system certifications, such as ISO9001, IATF 16949, or QC 080000, sign the Commitment to Comply with the Code of Conduct, and undertake the written review of suppliers. A subcontract processing supplier is required to pass the on-site audit.

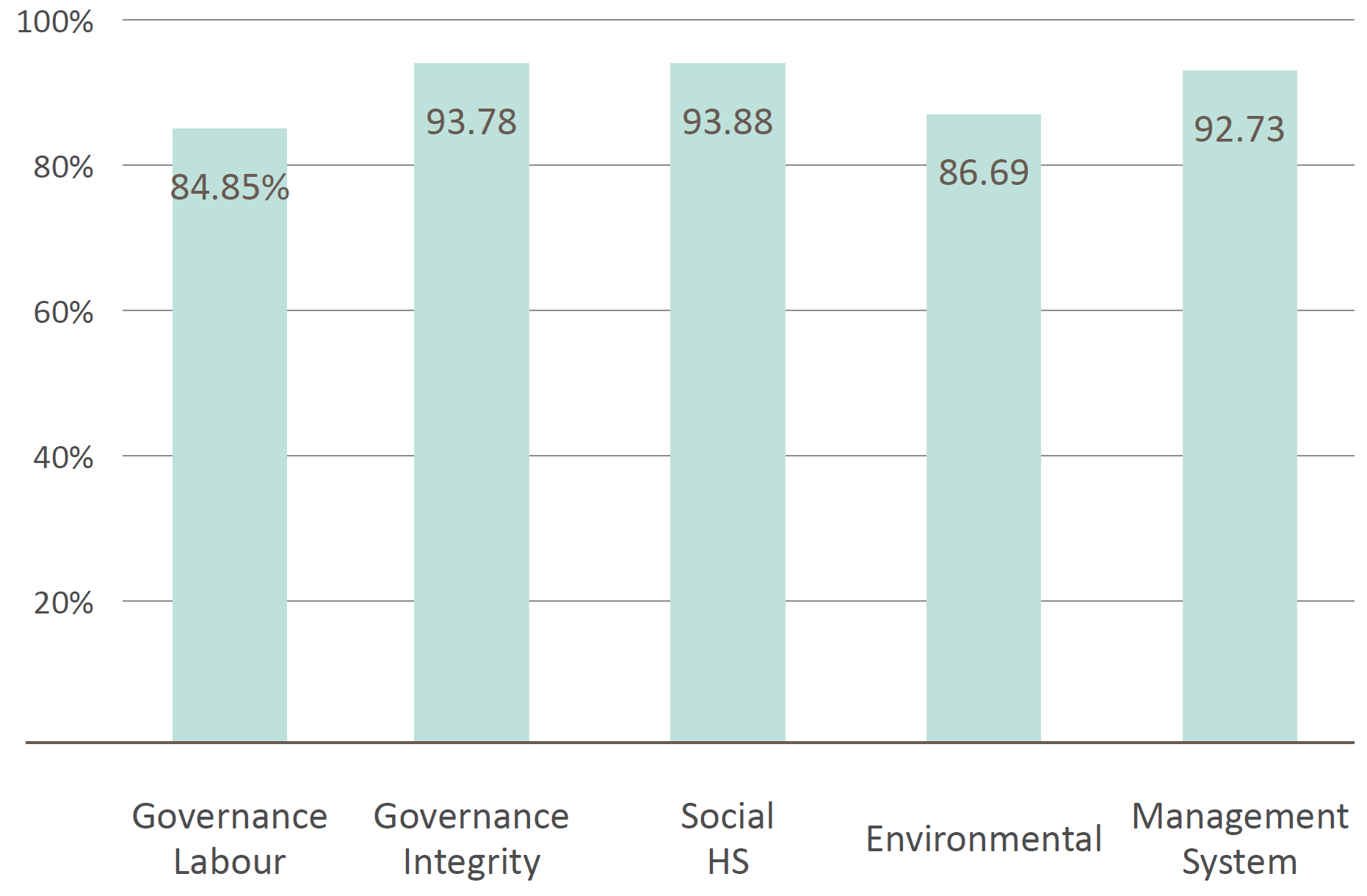

Any supplier with a self-evaluation result under 80 is subject to education and training to better their knowledge on the basic concepts of ESG & RBA so as to support suppliers in the ESG & RBA practices that follow. There was no supplier that failed the self-evaluation in 2022.

Supplier Evaluations

At present, approximately 94.1% of the suppliers on the raw material supply chain of Nuvoton Technology have obtained environmental management system certification(s). A total of 11 packaging and testing services and top 80% suppliers of raw materials completed the ESG & RBA self-evaluations in 2022. After the review by Nuvoton Technology, all the results of self-evaluations of suppliers are higher than 80 points, meeting the requirements of the Company. The percentage of the respective self-evaluation indicators in 2022 are as follows. Based on the chart, the suppliers focused on Social_Health and Safety systems the most.