Consumer

- Smart HMI

-

Re-Timer IC for USB4® Devices

-

HMI Platforms and Graphical Libraries Introduction

-

Wireless Smart Thermostat

- Gaming Lighting and Cooling Fans Control

-

New HMI Platform NuMaker-HMI-MA35D1

- GPS Tracker for Pet

- Soy-milk Maker Driver

-

Bluetooth Toothbrush Reference Design

- CSP MOSFET

- TWS Charging Box

- M031BT dual mode gaming mouse solution

- Four-in-one Smart Electronic Lock

- Advance Headset

- Baby Gear

- DSC / DVC

- DVR

- ELA

- Game Console

- Home Appliance

- Media Box

- Micro Printer

- Security Panel

- Smart Phone payment

- Smoke / CO Detector

- Sound Bar

- Toy

- Video Baby Monitor

- Voice Recognition

- WiFi CAM

- Kitchen Heating Appliance

- Wireless Charging

- Half-bridge Induction Cooker

- Smart Projector

- Laser TV

- 6-claw Robot

- Smart Plug

- USB Car Driving Simulator System

Industrial

- 48V Industrial Fan Motor Driver

- Totem Pole LLC EVB

- ARGB Fan Driver

- New Energy Gateway

- Industrial Weight scale

- Power Measurement

- Power Delivery 3.0 compliant DC Fan

-

MA35D1 HDMI Video Playback

- Digital Power Control

- Industrial Battery Monitoring IC

- NUC980 OpenWrt Graphical Gateway

- DALI Ecosystem - Control Gears and Devices

-

DALI Ecosystem - Application Controller

- High Voltage Fan Driver

-

Low Voltage Fan Driver

- Motor Parameter Identify Tool

-

Totem Pole PFC Reference Board

- Motor Driver

- Electric Scooter

- Air Purifier

- Out-of-band (OOB) Management Solution for Edge Devices

- Edge Computing for License Plate Recognition

- USB Type-C PD 3.0 TCPC and TCPM Solution

-

Battery Management System

- RF-GaN PA Module for 5G Base Station

- Servo Driver Module

- Elevator Call Board

-

Thermostat with Touch Key

- LoRaWAN ECO System

- DALI Digital Lighting Control

- Low Power ML51 Series Electronic Shelf Label

- Interactive Human Machine Interface Solution

- Plug and Play Iindustrial Measurement Development Platform

- IoT Development Platform

- NB-IoT IoT Development Platform

- Industrial Remote Terminal Unit

- Smart Water Meter

- Label Printer

- Face Recognition Attendance Machines

- 2D Bar Code Scanner

- Card Reader

- eBalance

- eBike

- Electricity Meter

- Face Recognition

- Fan / Ceiling Fan

- Fingerprint Identification

- Gas Meter

- Heat Meter

- POS

- QR Code Scanner

- Water Meter

- Smart battery management system

- BLDC Motor Control

- 8x8x8 LED Cube

- Door Access control system

- Elevator Control System

- LED Display

Smart Home Appliances

- TOF Solution

- M467 LVGL Display

- TFT Color Thermostat

- Virtual Reality (VR) Solution

- HDMI2.1 4x2 Matrix Solution

-

TOF sensing solution

-

Cold Chain Data Logger

- Color Display Wi-Fi Thermostat

- Smart Home Central Control utilizing IoT and Color Screen

- Smart Home Appliances with Video Playing Function

- Multi-Cloud Connection Platform

- TFT Thermostat

- Wireless Power Supply and Data Transfer Solution

- Machine Learning

- Intelligent Power Station

- PM2.5 Module

- OLED Display - GIF Format Decode (LZW) Supported

- Smart Toilet

IoT Security

- Matter for IT Monitor with Security

- M2354 for RTOS + PSA TF-M

- Cold Wallet Security

- CCTV VPN Security Module

- IoT Cloud-Ready Wireless Module

- Smart Sound Box

- IoT Secure Connection Solutions-1

- IoT Secure Connection Solutions-2

- Smart Meter for AMI 2.0

- Arm® Pelion Secure IoT Device Management Supported by M2351

- Fingerprint Secure IoT Door Lock

- USB FIDO Key for Identity Security

Audio / Video

- NSP2340T Voice Assistance with Touch Solution

- Smart Office UC Headset Solution

- Smart Office UC Speakerphone Solution

- NSP series voice assistance solution

- Noise reduction and echo cancellation solution

- Demo board template - ISD2361

- Bluetooth Audio

- Docking of iPhone / Android

- TV Audio

- WiFi A / V Streaming

- Wireless Microphone

- Wireless Speaker

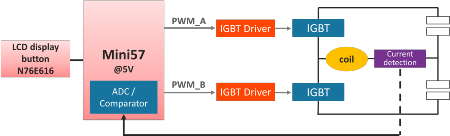

Half-bridge Induction Cooker

The electromagnetic induction heating technology used to converts 50 Hz AC low frequency to 17 ~ 35 KHz middle or high-frequency current, and then passes through the induction coil to form high-frequency magnetic fields that work with dedicated iron pots to generate powerful Eddy Current magnetic fields; metal atoms have fierce collision so can generates high temperatures promptly, which can achieve quick heating function.

The induction cooker solutions include monotube solution, half-bridge solution, and full-bridge solution. The monotube solution is suitable for 2 kW or less (mostly applied on home-use induction cookers). If needs fry function for high watt application, the power must reach 3 kW-15 kW, and if functions such as linear power regulation, maintaining boiling point and thermal insulation are required, then you will need a half-bridge solution; and the full-bridge solution is needed when heating power over 15 kW.

Nuvoton half-bridge induction cooker solution uses industrial-grade operating temperature: -40°C ~105°C MCU as the main controller, with embedded hardware safety protection mechanisms to achieve high performance and safety features; its maximum power can reach up to 15 kW and supports linear power adjustment as well as low power continuous heating (to maintain boiling point and thermal insulation, etc.) function. Multi-head stove solution is also provided to achieve centralized control and to coordinate the distribution power individually.

Single head stove/dual-head stove

- Introduction:

- Arm® Cortex®-M0, up to 48MHz, quick detection, real-time power adjustment, and safety protection.

- 12-bit 6-channel ADC, 2 comparators

- Multi-channel precision detection: Power grid voltage, current, IGBT temperature, reel temperature, the temperature under the pot and zero-crossing detection, etc.

- 48 MHz 16-bit 6-channel PWM (complementary dead zone)

- Effectively controls the IGBT switch, increases efficiency and prolongs the usage life

- The adjustable dead zone, compatible with various IGBT

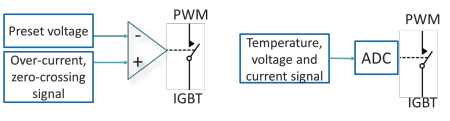

- Safety protection mechanisms:

Output protection including over-temperature, over-voltage, over-current, and surges, etc. (External signal can turn the PWM ON or OFF and set output status, achieving quick protection)

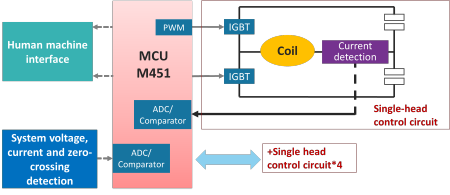

Multi-head stove (5 maximum)

- Introduction:

- Arm® Cortex ® -M4, up to 72 MHz, quick detection of the over-temperature/over-voltage/over-current of each stove, real-time adjustment and distribution of power and safety protection

- 12-bit 16-channel ADC, 2 comparators

- Multi-channel precision detection: Power grid voltage, current, IGBT temperature of each stove, reel temperature, the temperature under the pot and zero-crossing detection, etc

- 144 MHz, 16-bit 12-channel PWM (complementary dead zone)

- Effectively controls the IGBT switch, increase efficiency and prolongs the usage life

- The adjustable dead zone, compatible with various IGBT

- Safety protection mechanisms:

- Output protection including over-temperature, over-voltage, over-current, and surges, etc. (External signal can turn the PWM ON or OFF and set output status, achieving quick protection)

- Centralized control and coordinate the distribution of overall power

Solution features:

- Supports linear power output and low power continuous heating, maintain boiling point and thermal insulation functions: Half-bridge circuit flexibly adjusts the charge and discharge time of the upper and lower arm IGBT

- Multiple safety protections: Food tossing, over-temperature, over-voltage, and over-current, etc. Signal hardware including the 12-bit 6-channel ADC and 2 comparators turns the PWM ON or OFF directly

- Increases efficiency and prolongs usage life: 16-bit PWM (complementary dead zone) can control the IGBT switch effectively

Related IC: