Quality Management

Quality Management Program

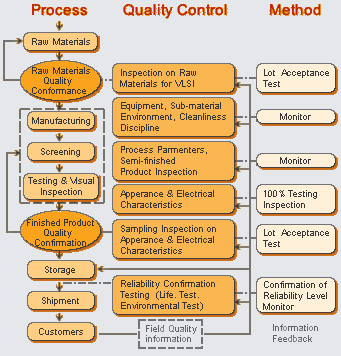

The purpose of Quality Management Program at Nuvoton is to establish the controls needed to assure that the quality and reliability of our VLSI products fully satisfy our customers. We strive to deliver competitive products free from defects and to provide our customers with prompt and professional service. Our Quality Management Program focuses on three major areas: quality control, reliability assurance, and failure analysis. Quality Control Nuvoton has implemented a series of quality control functions that cover all the steps in manufacturing process. The main steps in this quality control procedure are:

- Incoming materials inspection

- Wafer processing

- Electrical characteristics testing

- Chip assembly

Constant monitoring on all steps in the manufacturing process and information feedback at all levels allow fast and efficient detection of problems, evaluation and analysis, and corrective measures. We emphasize that each step in the manufacturing process should be undertaken with a "Do it right at the first time" attitude and must produce a defect-free output. The overall result is a line of high-quality and reliable products.

Reliability Assurance

At Nuvoton, the aim of reliability assurance testing is to assure high-level product performance throughout the intended product life. Each manufacturing phase is subject to continuous review, analysis, and evaluation, with modifications introduced to further improve quality and reliability. Our reliability system is based on three important sources of reliability data:

- Release qualification tests

- Real time monitor and conformity tests

- Field failure information

Failure Analysis

Failure analysis, which determines the cause of product failures and proposes corrective action, is an important part of reliability assurance. At Nuvoton, scanning electron microscopes, diagnostic probe stations, optical microscopes, and many other precision instruments are used to perform failure analysis on devices submitted from various sources. Defective ICs are logged into the laboratory for inspection and preparation of corrective action reports.

Packaging Technology And Subcontractor Management

Nuvoton works closely with assembly subcontractors to provide the best possible package form to maximize a device's performance and to meet customer's special demands. Our subcontractors have to follow strictly through extensive selection, qualification, and management programs to insure the delivery of high-quality products. In addition, Nuvoton conducts a rigid program to monitor package reliability which helps to insure the mechanical integrity of every package type produced by each production facility.

Quality Assurance Flowchart