Nuvoton battery management system solution

Lithium ion batteries can be categorized into three types according to the application scenario: “Power”, “Commercial” and “Industrial and Energy Storage”. Even though the growth of traditional electronic products that use lithium ion batteries is slowing, such as smartphones, notebook computers and digital products, the demand for lithium ion batteries has increased in recent years by many innovative emerging industries such as power tools, VR glasses, drones and wearable devices. The key applications of lithium ion batteries will mainly be for fields such as power tools.

Since the materialistic properties of a lithium ion battery made it so that it cannot be overcharged, over-discharged, over-current, short-circuit and charged/discharged in extremely high temperatures, and due to the limited capacity density in a single lithium battery, several lithium batteries usually have to be connected in serial or parallel for use according to different application scenarios. Therefore, safety devices need to be designed to protect and manage the lithium batteries in order to prolong the usage life of the batteries and avoid unnecessary dangers from happening.

A battery management system is an electronic device that can monitor and manage batteries. Its main function is to test the various status parameters of the batteries including the voltage, total voltage, current and temperatures, in individual batteries. It also simulates the front-end to collect data and perform SOC estimation and battery balancing to further control the charging/discharging processes of the battery. It is a management system that protects batteries and increases comprehensive performance of batteries. We call the battery management system of the power and energy-storage fields BMS, and the battery management system in the commercial and some of industrial fields with fewer batteries CPB (cell protection board).

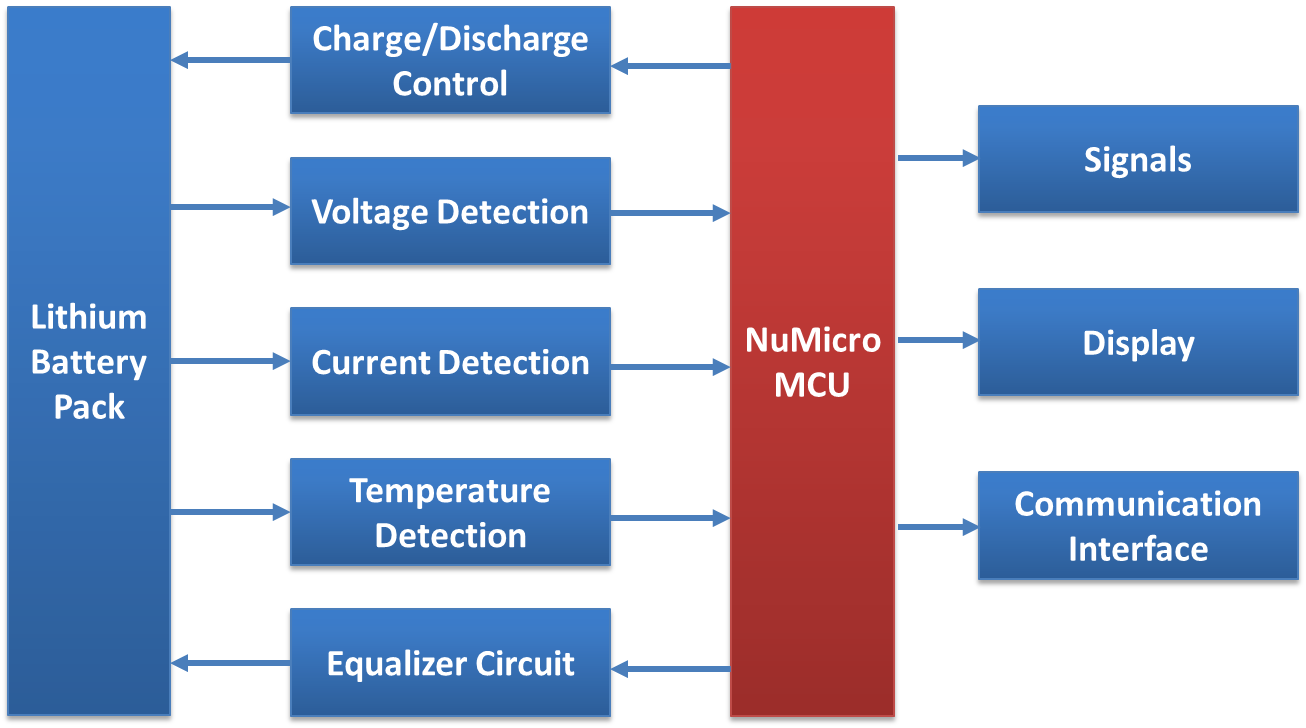

The number of batteries for CPB usually does not exceed 20; the protection board can be categorized as pure hardware or MCU-based smart lithium battery protection boards. Compared to pure hardware, the adjustment of MCU-based smart protection board parameters is easier, more flexible, and has better function designs to satisfy customer needs. The composition of conventional smart battery protection board is as shown in the figure below:

As for the diversified needs of CPB, Nuvoton’s high performance NuMicro Cortex – M0 MCU provides: (1) 5V working voltage is supported for the entire series, and expanded selection range of peripheral analog devices to effectively lower cost for the customers; (2) multi-channel high-speed 12-bit ADC to respond to instant voltages, currents and temperatures changes of each battery, so that processing can be performed in real-time to prevent overcharging, over-discharge and over-temperature of batteries; (3) there are rich communication ports on-board including UART, IIC, SPI and CAN, able to satisfy communication needs such as simulating front-end IC with peripherals, host computer and chargers simultaneously; (4) super low-power standby and operations, able to effectively reduce the power-consumption of the system and extend battery operating time; (5) -40 to 85/105 degrees operating range can effectively ensure the stability and reliability of system operations; (6) provides several packaging and Flash sizes to give you more choices.

Nuvoton also provides 8-bit MCU with high performance/cost ratio and low pin count for different application field needs, bringing you more selections.