M4 microcontroller M487KMCAN with Super Large 2.5 MB Flash for Thermal Printers

Thermal printing was first used on facsimile machines. It converts the received data into dot matrix signals to control the thermal unit to heat the print head that prints images on the coated thermochromic paper by selective heating. Thermal printers are comprehensively on POS systems, banking systems, and medical instruments.

The working principle of a thermal printer is that semiconductor heating elements are equipped on the print head for the thermal printer to print images by selectively heating on the coated thermochromic paper. Heat is generated by a small electronic heater on the print head, contacting the coated thermochromic material. The printer’s control logic controls the heater aligned in a rectangular or bar dot matrix. Being driven, it generates heat to print images corresponding to the heating elements. The logic circuit controlling the heating elements also controls paper feeding to print the corresponding images on a label or paper.

A thermal printer comprises the following key components:

- Print head: Heading device (elements), sensors, paper feeder, and paper cutter.

- Control board: Power supply, controller, serial communication port, font file, status detection, and indication circuit, feeder motor driver, cutter driver.

- Shell structure: Fixing device, paper storage cabinet, and paper holder.

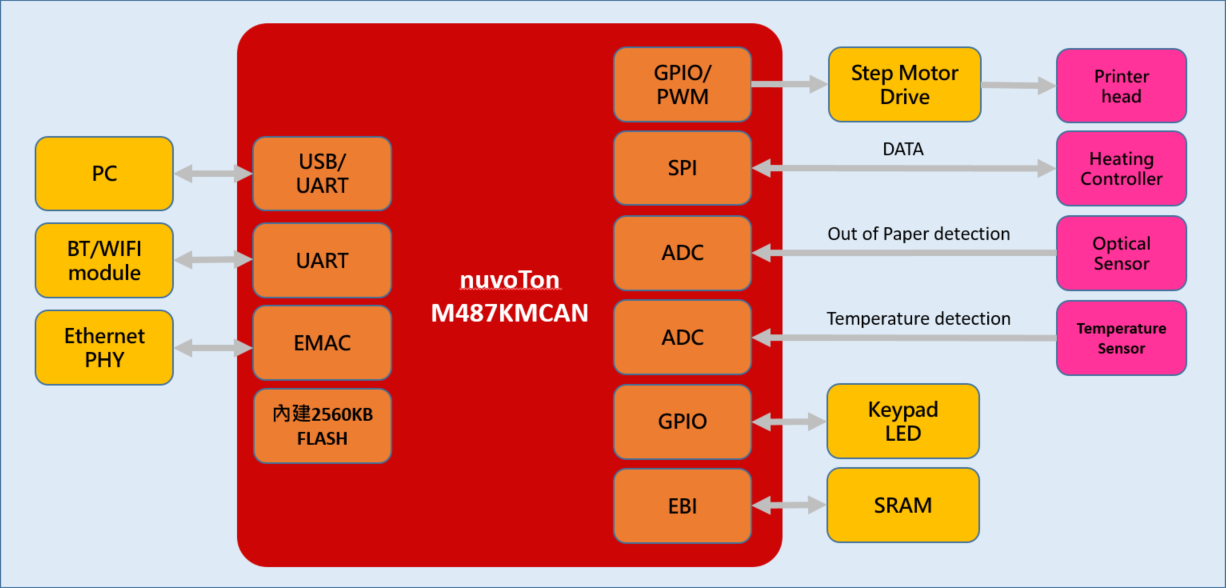

M487KMCAN Solution for Thermal Printers:

The M487KMCAN thermal printer solution is based on the M487KMCAN single-chip microcontroller equipped with 2560KB FLASH memory for storing a large number of font files. In communication, the microcontroller supports communication with the computer and other hosts via the UART port or USB port. By linking the Bluetooth or Wi-Fi module via the UART port, it supports TCP/IP network connection over 10/100-based Ethernet PHY. In print head control, the microcontroller controls the stepwise motors of the paper feeder and paper cutter via the GPIO or PWM stepwise motor drive circuit. A serial port interface (SPI) is equipped for transmitting printing data required by the print head in SPI protocol. An analog-digital converter (ADC) is provided to gather analog voltage from the optical sensor for paper shortage detection. The ADC collects the analog value from the temperature detection circuit and shuts down the print head power supply when the temperature is higher than the default value for overheat protection. The multi-channel general-purpose input/output (GPIO) cab serves as the output control of keystrokes and indicators.

Advantages of the M480 Series

- Supports quick printing through connection with print heads via high-speed SPI at 96MHz and process data with a 192MHz core.

- Supports USB high-speed/full-speed interfaces with on-chip PHY to reduce materials demand.

- Cuts external SPI Flash costs and reduces PCB sizes when using with the M487KMCAN.

Features of M487KMCAN

- Supports quick printing with a core speed up to 192MHz.

- Sufficient memory space up to 2560KB Flash/128KB SRAM for storing a large number of font files.

- Comprehensive communication interfaces up to 11 UART ports (6x LPUART + 3x ISO7816 UART + 2x USCI UART)

- Supports TCP/IP network connection over 10/100-based Ethernet

- Hardware cryptographic accelerators speed up cryptographic operations and reduce CPU workload.

- Supports 2 USB OTG (high speed and full speed) ports for connecting external USB devices.

- Supports 2 SD card readers (up to 2x 32GB)

- Supports EBI for add-on SRAM storage (up to 3x 1MB)

- Supports up to 16 ADCs for temperature sensors and other sensors.